For a list of parts included with the cylinder head click here

The KAD 16 valve Twin Cam head conversion is simply in a different league where A series cylinder head comparisons are made. The efficiency of 4 valves per cylinder cannot be matched in its power potential by older designs. Plenty of valve area, well shaped ports and a compact pent roof combustion chamber all contribute providing copious top end power whilst still pulling well from low revs

The Twin Cam head conversions fit onto any 1275cc A series cylinder blocks. The Cooper S and A+ blocks are best to use as the GT block appears to distort badly when hot. There are a few simple modifications required to the block to accommodate the Twin Cam head, but the main divergence from 5 port practice is in the pistons. With a larger combustion chamber volume than a 5 port, it is necessary to run flat top pistons which require valve clearance pockets to be accurately machined into the piston crown. This is a specialist machining operation which KAD can offer to customers if required. Forged pistons are preferred for their strength and are essential above 130bhp. The original camshaft is retained to drive the oil pump and the distributor.

Arrow rods, forged crank and a 4 bolt centre main cap, this 1460 produces 181bhp @8000rpm

Arrow rods, forged crank and a 4 bolt centre main cap, this 1460 produces 181bhp @8000rpm

The bottom end build for a Twin Cam will depend very much on its anticipated power output. A the lower stage of tune it is possible to use A+ cranks and rods, helical drop gears and a standard 4 speed A+ box with a Twin cross pin diff. Whilst this will give reliable service upto 120 bhp, above this it is asking rather a lot from components designed for sixty-odd horsepower. Stage two conversions and above should use EN40B nitrided steel cranks and rods, either from forgings or billet and a 4 bolt steel centre main bearing cap should be fitted to hold the crank in place and give the bearings a chance.

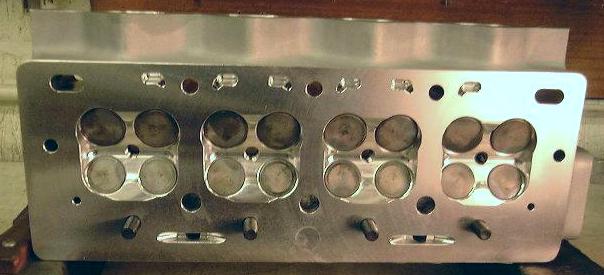

Two versions of the heads are made, the small valve head, with superior low end torque is suitable for road use with a maximum power potential of 160bhp. The big valve race version with larger valves and ports sacrifices a degree of low down pull for increased mid range and top end power

The cylinder head and cam carrier are sand cast in L99 aluminium alloy which is then heat treated to provide castings of a high material integrity, freedom from porosity and shrinkage and a material that machines well and remains stable at elevated temperatures. The heads and other castings are CNC machined to close tolerances at our factory. After each head has been gas flowed and polished, lead free valve seat inserts and bronze guides are fitted. Three angle valve seats are cut and each valve is carefully lapped in by hand to ensure the stainless steel valves seal perfectly. Two piece valve springs are used which allow up to 0.440" cam lift. The twin camshafts are CNC machined from EN40B nitriding steel and run on steel bucket cam followers. Valve clearance is adjusted through the use of tappet shims. The cams are belt driven from the crankshaft, with a series of pulleys and tensioners mounted onto a billet alloy front plate (which replaces both the original tin timing cover and backplate). Adjustable cam timing pulleys are used to allow accurate cam timing

Cam profiles stocked:

- KAD2 0.360" lift (9.14mm) 264 degree duration, road cam, good low down torque

- L14 0.415" lift (10.54mm) 280 degree duration, fast road/rally/hillclimb good low down torque, good top end

- L1 0.408" lift (10.36mm) 306 degree duration, Race cam. Used in combination with a BD3 exhaust, this is the old BDA rallycross combination which gives excellent all round performance for fast road, rally, hillclimb. We have seen 185bhp on our dyno from a 1380 running L1/BD3.

- F1 0.412" lift (10.46mm) 324 degree duration, Race cam, favours high revving short stroke engines

- BD30.348" lift (8.83mm) 290 degree duration, use with L1 inlet

- BD4 0.431" lift (10.94mm) 316 degree duration. Race cam, a wilder version of the L14

Specials are also available although our standard range should cover most requirements. See Kent Cams website for additional cam profile information.

The heads can be run with either conventional carburettors or engine management systems. On carburetted engines we use and recommend the Weber DCOE types, 40 DCOE for the small valve head and 45 DCOE for the big valve head. They are good power producers, have a worldwide spares availability and there are plenty of people who are good at setting them up. The various programmable engine management systems are better in terms of smoother torque delivery, better fuel economy, superior emissions and their electronic precision but there are still many drivers who favour a simpler mechanical set up.

With carburettors it is necessary to use either a conventional distributor with electronic ignition pack or a programmable distributor-less ignition, which reads an rpm signal from the crank.

Engine management systems are the ultimate: their programmable ECU's provide accurately controlled fuelling and ignition control at each and every combination of throttle angle and engine speed. This base reading is then modified by sensors reading temperatures and pressures to provide the optimum operating conditions for power, economy and emissions. The engine management system must be calibrated to the engine in question either on an engine dyno or rolling road. The typical installation would use a pair of twin throttle bodies, 40-45mm diameter, having the DCOE flange pattern.

KAD recommend using the Weber Alpha Engine Management system which is a tried and tested, well engineered product. As it provides all of the specialist parts required it is very good value for money (which some other systems do not).

The gearbox and transmission required will depend largely on the use to which the engine is being put and to the torque output of the engine. It is the torque and not the horse power of an engine which is responsible for destroying transmissions so the approach for the Twin Cam should be the same as that for a race engine.

The standard helical 4 speed can be used but is really only suitable for stage one conversions up to 120bhp. Even at this level the standard diff is an immediate weak link and should be the priority for change since the standard cross pins are very weak. The twin cross pin types on the market are a good fix on a budget as limited slip types require drive shaft and inner CV changes to remain reliable.

Stage two and above must use uprated transmission components throughout with dog engagement gearboxes required for stage three and four. As with the gearboxes, clutches and flywheels also need to be addressed in the same fashion. The stage one engine can use the heavier Verto type flywheel with turbo clutch cover but for most uses our lightweight alloy flywheel is best to use, giving good idle characteristics and aiding the engines crisp free revving nature. The grey diaphragm clutch cover should be used from stage two up with organic plates being used up to stage three.

Specifications

- 1011001 Road spec: small valve 27mm x 23.7mm valve head diameter

- 1011002 Race spec: big valve 30.4mm x 26mm valve head diameter

Price: $1,849.95

View

Special Order

Price: $1,895.00

View

9/13/2017 2:00:00 AM

1849.0000

Special Order